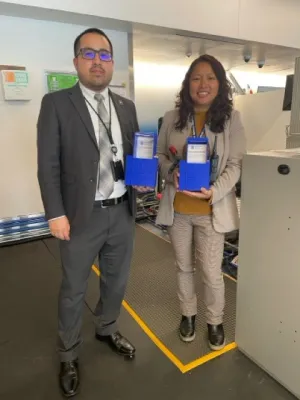

Montgomery Regional Airport TSA Manager Robert Allen and Lift Team Alabama member Austin Gastonguay alongside the WTMD barrier. (Photo by Regina Dixon)

Montgomery Regional Airport TSA Manager Robert Allen and Lift Team Alabama member Austin Gastonguay alongside the WTMD barrier. (Photo by Regina Dixon)

TSA has been an agile agency since its creation. Built from the ground up in the wake of 9/11, TSA had no choice but to respond and adapt to a changing threat environment.

Two decades later, the spirit of innovation is alive and well at TSA. Frontline employees – the heartbeat of the agency – are intensively involved in making practical changes that support TSA’s vital mission while further enhancing the passenger experience.

Local Innovation for TSA (Lift) Cells, hubs of innovation that are instrumental in inventing solutions to the daily challenges the workforce faces, have identified more than 250 problems they are working on to help Officers become better, faster and more efficient in protecting the traveling public and keeping passenger satisfaction high.

Here are just a few of the innovations Lift Cells have been working on across the nation:

Walk-through metal detector barrier

A common problem for many airports across the country is they don’t have anything to block passengers from accessing the walk-through metal detector (WTMD) when officers need to step away.

“I knew this was an issue for some airports, but I was shocked from the feedback from the other Lift Cells that this was an issue for all size airports across the nation,” said Montgomery (Alabama) Regional Airport TSA Manager Robert Allen. “The idea of the walk-through barrier originated when I was at Bellingham International Airport (BLI) in Washington. We had a barrier made of cardboard that was falling apart. One of our screening officers, Gordy Lucrisia, made a PVC barrier and brought it in. It worked great.”

When Allen moved to College Station, Texas, to work at Easterwood Airport, he noticed there was no WTMD barrier. Allen asked Lucrisia for photos of the barrier at BLI. Allen then went to work, saying, “Some of the changes I made were to paint it TSA blue and add a sign that instructed passengers and crew to please wait. The staff were thrilled with the barrier. There were even times when crewmembers coming through asked to take pictures of it.”

When Allen moved on to work at Montgomery Regional Airport, one of the first things he did was build a barrier with more enhancements.

“Again, I was shocked they had nothing blocking the WTMD,” Allen said. “I found furniture grade PVC in TSA blue. It’s a heavier-duty PVC and looks very professional. I had another member of the Alabama Lift team assist me in the construction. It has worked great, and we look forward to making them for airports in the entire state.”

Allen compared the barrier they built to a barrier you could buy on Amazon or from another vendor. The officers tested it for a day and reviewed the Amazon barrier and the one they built. “The staff did not hold back. They hated the Amazon barrier,” Allen said. “On a 1-5 scale, they gave it an average rating of 1.07. The barrier we built rated an average of 4.73.”

At the Spring 2024 Lift Summit, Allen updated other Lift Cells and said, “They were excited to go back to their home airports and look into building their own barriers.”

Backpack strap gap filler

The Helena Regional Airport (HLN) Montana Lift team worked diligently to identify problems and come up with solutions to everyday issues officers encounter at the checkpoint.

The gap filler at the X-ray entrance tunnel was posing a problem because straps were getting caught in the small crack under the post of the entrance of the X-ray. The HLN Lift team created a fix to prevent baggage from getting snagged on the conveyor belt.

“There was a gap in the side posts where the bags enter the X-ray. The gaps were wide enough where backpack straps were getting caught and causing a jam inside the X-ray machine,” said TSA Manager Michael Ellis. “The Lift team designed and 3D printed an L-shaped cover that fit perfectly around the post, covered this gap and stopped straps from getting caught there. Since it was implemented, we have never had a strap get caught again.”

Since the gap filler worked so well, Ellis took the design and samples to the 2023 Lift Summit and showed other Lift Cell teams.

“The other Lift Cell team members liked it so much, they asked if they could get some for their airports as well,” Ellis said.

These have become so popular, TSA HLN printed over 300 backpack strap gap fillers, which over 25 airports are now using.

“This is what innovation and Lift is about,” Ellis said. “Airports are sharing ideas and designs so we can help each other solve some of the many problems our officers face every day working at the checkpoint.”

Notice of Inspection toolkit

The innovation journey often begins with identifying pain points and seeking creative solutions. After attending a Lift Summit at Los Angeles International Airport (LAX), TSA Manager Kevin Peinado explored ways to improve daily workforce activities in the checked baggage area.

The storage method used for Notice of Inspection (NOI) inserts involved converting glove boxes into makeshift containers and taping them at checked bag search tables. NOIs are legal notices placed in checked baggage after TSA inspection. They tell passengers that TSA officers opened and inspected their bag and provide contact information in case travelers have questions about the search.

Not only did the old storage method look messy, but it lacked professionalism. Peinado noted, “Our Officers deserve better.”

Recognizing the need to improve, Peinado and LAX Mission Support Administrative Assistant Maria McCants brainstormed solutions. The initial step involved using a prototype of clear plastic rectangular boxes to hold NOIs and attaching them to the nearest wall. The simple change garnered positive feedback, but the quest for improvement didn’t stop there. Through interviews with officers, Peinado and McCants gained valuable insights.

It became clear the TSA team needed additional compartments for ziplock ties, box cutters and TSA keys. Prototype 2 was born, featuring clear plastic boxes with compartments on each side. After a two-week trial period, the LAX team collected more feedback, confirming the success of Prototype 2. However, officers expressed dissatisfaction with the box being taped to the wall.

Prototype 3 addressed this concern by adding magnets to the back of the box, making it portable. This innovation allowed officers to position the box closer to their work area and adapt quickly in case of contingencies at the checked baggage area.

McCants created a design sketch complete with measurements to communicate the design to a 3D printing service. The sketch included details and dimensions to ensure accurate production of the prototype. The 3D printed version is more durable and easy to use. TSA conducted production and cost-benefit analyses to ensure scalability efforts align with the budget and will provide favorable return on investment.

Peinado presented the concept during the LAX senior leadership biweekly meeting with LAX TSA Federal Security Director Jason Pantages, who supported the plan. The idea quickly spread to other terminals at LAX with requests for similar boxes. LAX Lift partnered with the U.S. Air Force’s Spark Cells, which are a decentralized network of Air Force bases around the world to execute locally generated ideas and projects. This partnership led to the 3D printing of the boxes. The latest prototype features stronger and more durable compartments.

“The Team LAX Lift Cell journey of innovation showcases the power of collaboration, user feedback and adaptability in finding practical solutions to workplace challenges,” Peinado said. “It ultimately leads to enhanced efficiency and professionalism in the checked baggage screening area using the NOI toolkit.”

By Mike Frandsen, TSA Strategic Communications & Public Affairs